Basic

Concepts

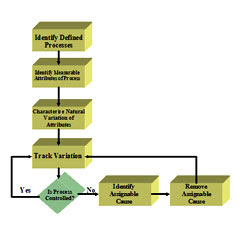

- Statistical Quality Control or Statistical Process Control (SPC) is an effective method of monitoring a process through the use of control charts.

- Control charts enable the use of objective criteria for distinguishing background variation from events of significance based on statistical techniques.Much of its power lies in the ability to monitor both process center and its variation about that center.

- By collecting data from samples at various points within the process, variations in the process that may affect the quality of the end product or service can be detected and corrected, thus reducing waste as well as the likelihood that problems will be passed on to the customer.

- its emphasis on early detection and prevention of problems, SPC has a distinct advantage over quality methods, such as inspection, that apply resources to detecting and correcting problems in the end product or service.

- In addition to reducing waste, SPC can lead to a reduction in the time required to produce the product or service from end to end. This is partially due to a diminished likelihood that the final product will have to be reworked, but it may also result from using SPC data to identify bottlenecks, wait times, and other sources of delays within the process.

- Process cycle time reductions coupled with improvements in yield have made SPC a valuable tool from both a cost reduction and a customer satisfaction standpoint.

Statistical

Process Control was pioneered by Walter A. Shewhart in the early

1920s. W. Edwards Deming later applied SPC methods in the United

States during World War II, thereby successfully improving quality in

the manufacture of munitions and other strategically important

products. Deming was also instrumental in introducing SPC methods to

Japanese industry after the war had ended.

Shewhart

created the basis for the control chart and the concept of a state of

statistical control by carefully designed experiments. While Dr.

Shewhart drew from pure mathematical statistical theories, he

understood that data from physical processes seldom produces a

"normal distribution curve" (a Gaussian distribution, also

commonly referred to as a "bell curve"). He discovered that

observed variation in manufacturing data did not always behave the

same way as data in nature (for example, Brownian motion of

particles). Dr. Shewhart concluded that while every process displays

variation, some processes display controlled variation that is

natural to the process (common causes of variation), while others

display uncontrolled variation that is not present in the process

causal system at all times (special causes of variation).

Process Control

Process control

is a statistics and engineering discipline that deals with

architectures, mechanisms, and algorithms for controlling the output

of a specific process.

For example, heating up the

temperature in a room is a process that has the specific, desired

outcome to reach and maintain a defined temperature (e.g. 20°C),

kept constant over time. Here, the temperature is the controlled

variable. At the

same time, it is the input

variable since it

is measured by a thermometer and used to decide whether to heat or

not to heat. The desired temperature (20°C) is the set

point. The state

of the heater (e.g. the setting of the valve allowing hot water to

flow through it) is called the manipulated

variable since it

is subject to control actions.

A commonly used control device called a

programmable logic controller, or a PLC is used to read a set of

digital and analog inputs, apply a set of logic statements, and

generate a set of analog and digital outputs. Using the example in

the previous paragraph, the room temperature would be an input to the

PLC. The logical statements would compare the set point to the input

temperature and determine whether more or less heating was necessary

to keep the temperature constant. A PLC output would then either open

or close the hot water valve, an incremental amount, depending on

whether more or less hot water was needed. Larger more complex

systems can be controlled by a Distributed Control System (DCS) or

SCADA system.

In practice, process control systems can be

characterized as one or more of the following forms:

- Discrete – Found in many manufacturing, motion and packaging applications. Robotic assembly, such as that found in automotive production, can be characterized as discrete process control. Most discrete manufacturing involves the production of discrete pieces of product, such as metal stamping.

- Batch – Some applications require that specific quantities of raw materials be combined in specific ways for particular durations to produce an intermediate or end result. One example is the production of adhesives and glues, which normally require the mixing of raw materials in a heated vessel for a period of time to form a quantity of end product. Other important examples are the production of food, beverages and medicine. Batch processes are generally used to produce a relatively low to intermediate quantity of product per year (a few pounds to millions of pounds).

- Continuous – Often, a physical system is represented though variables those are smooth and uninterrupted in time. The control of the water temperature in a heating jacket, for example, is an example of continuous process control. Some important continuous processes are the production of fuels, chemicals and plastics. Continuous processes, in manufacturing, are used to produce very large quantities of product per year (millions to billions of pounds).

Applications having elements of

discrete, batch and continuous process control are often called

hybrid

applications.

1 Comments